Technical Material

Overview and Characteristics of Fan

A cooling fan is widely used to extend life of your system by cooling off heat of the system that many electrical components are mounted in a very high density and dissipating heat. Since we SANYO DENKI developed “San Ace” which is the first AC fan in Japan in 1965, we have increased fan motor lineup until now meeting customer's needs rapidly based on our tremendous career. We SANYO DENKI will continue to develop new fans with high airflow, low noise, low vibration, and energy-saving design.

We can roughly devide fan into two types which are AC and DC.

AC fans SANYO DENKI succeeded in the mass-production of AC fans in 1965. SANYO DENKI was the first Japanese manufacturer to have succeeded at this.●High performance ●High reliability ●Safety |

DC fans SANYO DENKI succeeded in the mass-production of DC fans in 1982.●High performance ●Low power consumption ●Low vibration ●Low leakage of flux ●High reliability |

SANYO DENKI currently has a wider variety of products like Long Life Fan, Splash Proof Fan, and Oil Proof Fan, Blower, Centrifugal Fan etc to meet all customer needs.

A cooling fan generally cools itself as well.

The temperature rise of the motor is relatively low and the temperature rise of the grease in the bearings is also low, so expected life is longer than general some either motors.

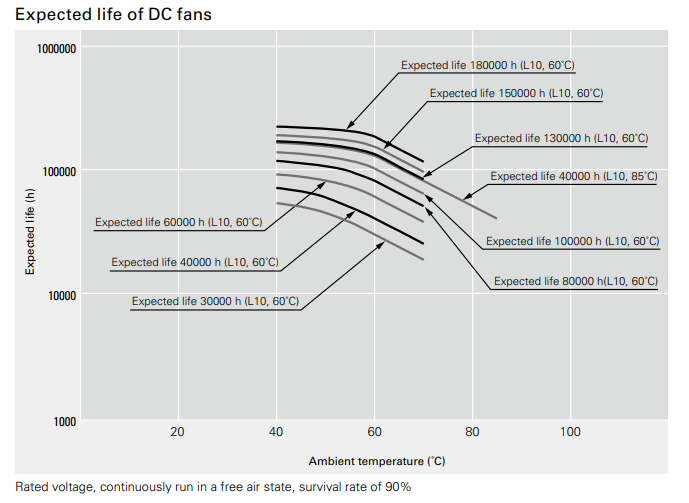

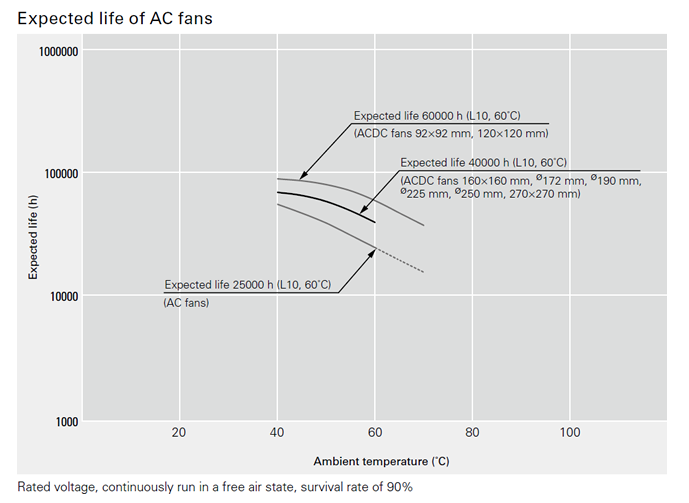

Since the ser vice life of bearings is a theoretical value that applies when they are ideally lubricated, the life of lubricant can be regarded as expected life of the fan. DC fan consumes less power and its temperature rise of bearing is very low. When the measurement conditions are: L10 (the remaining product life in the lifespan test is 90%), with an ambient temperature of 60°C (85°C for Wide Temperature Range Fans), at the rated voltage, and continuously run in a free air state.

The table below indicates the relationship between ambient temperature and expected life estimated on the basis of our life tests and same other tests conducted by SANYO DENKI.

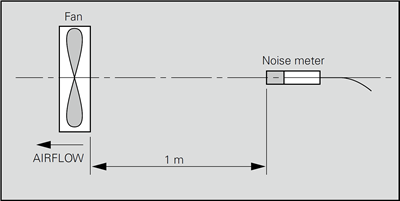

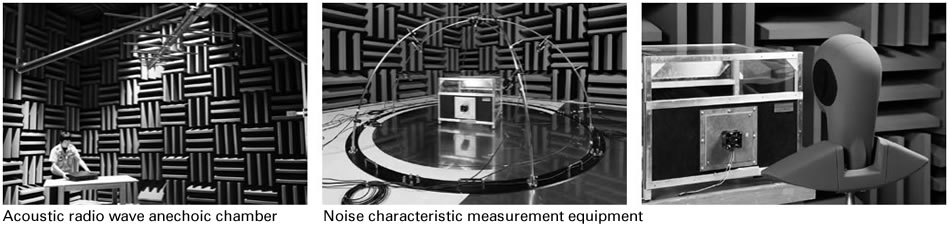

Noise is average value that measured at 1 meter away from air intake side of fan that is suspended on special frame in anechoic chamber (as per JIS B 8346).

Acoustic radio wave anechoic chamber

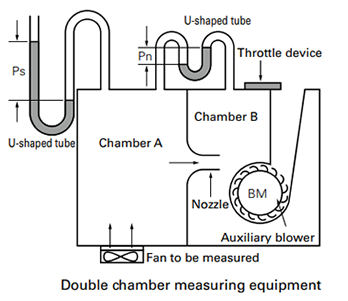

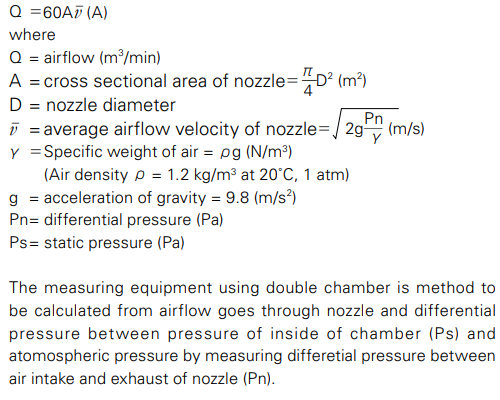

It is very difficult to measure airflow and static pressure. In fact, the performance curve may vary greatly according to the type of measuring equipment.

The commonly-used type of measuring equipment is a wind tunnel using a Pitot tube. SANYO DENKI uses a very precise method using double chamber equipped with many nozzles.

Static pressure

1 mm H2O=0.0394 inch H2O1 mm H2O=9.8 Pa (Pascal)

1 inch H2O=25.4 mm H2O

1 Pa=0.102 mm H2O

1 inch H2O=249 Pa

Airflow

1 CFM (ft3/min)=0.0283 m3/min1 m3/min=16.67 ℓ/s

1 CFM=0.472 ℓ /s

1 ℓ /s=0.06 m3/min

Last updated: November 2025